Wastewater Treatment before its disposal & its recycle has become an important these days. With growing population & diminishing fresh water resources, water recycling has become the need of this hour. We manufacture & supply Sewage Treatment Plants, Greywater Treatment Plants & Effluent Treatment Plants to our clients. Traditional technologies are combined with latest advancements to improve the quality of the water to make it recyclable at minimum running costs. We always maintain best engineering practice & our plants will always have following advantages:

A Grey Water Treatment Plant is a system that treats wastewater from showers, sinks, and laundry, excluding toilet waste. This type of water, known as grey water, contains fewer contaminants than black water and is therefore easier to treat. It uses filtration, biological processes, and disinfection to clean the water.

In Greywater Treatment Plant two method is commonly used, First one is Continue Mixing Reactor and other is Sequencing Batch Reactor

Continue Mixing Reactor based GWTP: In this process, air is continuously supplied into the aeration tank to keep the water

mixed.

In Greywater Treatment Plant Sequencing Batch Reactor is operate in Seven batch per day

Sequencing Batch Reactor: It is a type of batch reactor used in wastewater treatment that operates in discrete cycles. It involves a series of stages: filling, reacting, settling, and decanting, all occurring in the same tank.

A Sewage Treatment Plant is a facility designed to treat and purify domestic wastewater, commonly known as sewage, before it is safely discharged into the environment. Sewage typically includes water from toilets, bathrooms, kitchens, and laundry. The treatment process involves several stages,

starting with screening to remove large solids, followed by sedimentation to settle heavy particles. Biological treatment then uses bacteria to break down organic matter. Afterward, the water goes through filtration and disinfection, often using chlorine or UV light, to eliminate harmful pathogens.

In Sewage Treatment Plant two method is commonly used, First one is Moving Bed Bioreactor and other is Sequencing Batch Reactor

Moving Bed Bio Reactor : It is a biological wastewater treatment technology that utilizes floating plastic media to support the growth of microorganisms, forming a biofilm. These carriers are kept in constant motion by aeration or mechanical mixing, providing optimal contact between the biofilm and the wastewater. The biofilm degrades organic pollutants and nutrients, such as nitrogen and phosphorus, in the water. MBBRs are efficient, space-saving, and capable of handling varying wastewater loads. We recently supplied 710KLD MBBR based STP.

Sequencing Batch Reactor : It is a type of batch reactor used in wastewater treatment that operates in discrete cycles. It involves a series of stages: filling, reacting, settling, and decanting, all occurring in the same tank. In Sewage Treatment Plant Sequencing Batch Reactor is operate in Five batch per day.

It is a facility used to treat wastewater, or effluent, generated from industrial processes. Industrial effluent often contains harmful chemicals, heavy metals, oils, and organic matter that can pollute water sources. The ETP process typically begins with preliminary treatment, where large particles and oils are removed. This is followed by chemical treatment to neutralize harmful substances and biological treatment to break down organic pollutants using microorganisms. ETPs are crucial for industries such as textiles, pharmaceuticals, chemicals, and food processing.

Biological Treatment Methods: These methods use microorganisms to break down organic contaminants in the effluent, making them biodegradable.

Activated Sludge Process: A biological process where air is bubbled through the wastewater, promoting the growth of microorganisms that degrade organic matter.

Trickling Filter: Wastewater flows over a bed of biological media, where microorganisms grow on the surface and treat the effluent as it passes over.

Moving Bed Biofilm Reactor (MBBR): Wastewater passes through a tank containing floating plastic carriers that provide surface area for bacteria to form biofilm, which degrades organic pollutants.

Sequencing Batch Reactor (SBR): A batch process where wastewater undergoes aeration and biological treatment in cycles, with each cycle consisting of filling, reacting, settling, and decanting.

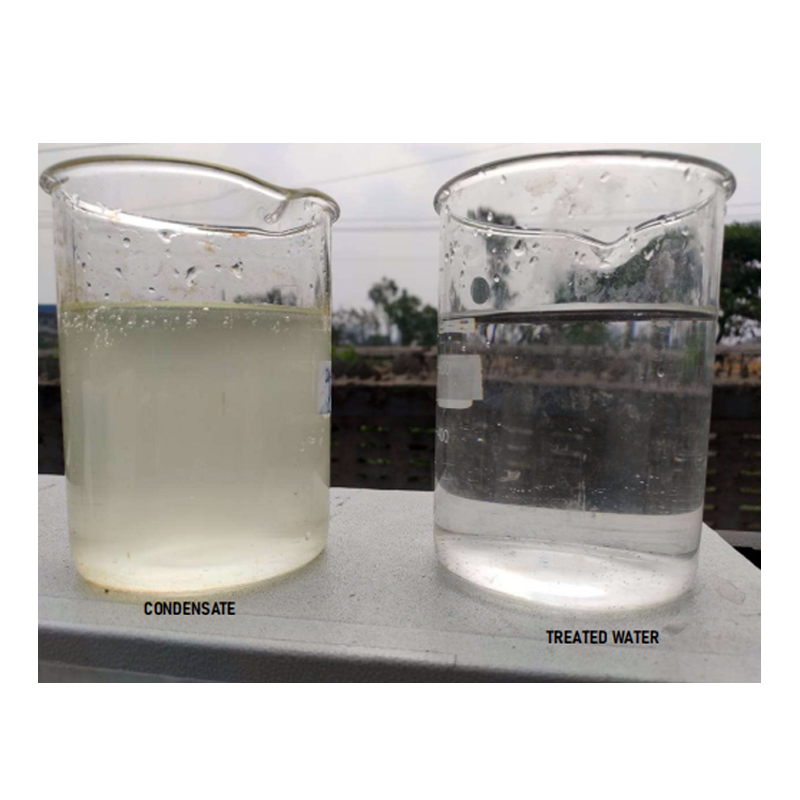

Condensate Polishing Unit: It is a specialized water treatment system designed to treat condensate water (the water recovered from steam in power plants, industrial processes, or other systems using steam) to remove impurities and ensure it meets the required quality for reuse or discharge.

MBBR tank By Diffuser

Sewage & Greywater Treatment Plants

Greywater Treatment Plant

Sewage Treatment Plant

Sequencing Batch Reactor Result

Condensate Polishing Unit Result